Repair Techniques

Common Repair Methodology

While every repair is different, there tends to be a common order of operations involved with similar concepts but very different methods of execution.

Inspection and Reverse Engineering

Atlas is versed in an enormous variety of machines and components, which makes us uniquely skilled in reverse engineering worn and damaged parts. A strong combination of machining, machine design, and engineering backgrounds enable our team to reverse engineer, redesign, and create a repair plan for critical components with confidence.

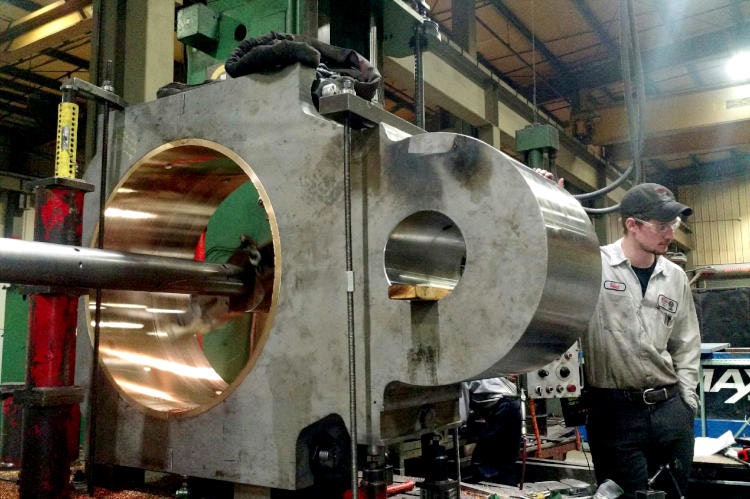

Material Removal and Preparation

A proper repair always begins with preparation of the affected area. This typically means removal of material – sometimes it’s grinding 0.001” off of the area, sometimes it’s turning inches of material off of a diameter, and other times might require parting a couple of feet off of the end of a tie bar or shaft. The name of the game is getting to clean, uniform material.

Material Replacement

Welding is one of the most common ways of adding material to a metal component, and it’s preferred when a lot of material must be added. Atlas has utilized TIG welding to repair a defect as small as a pore, utilized submerged arc welding to add over a ton (yes, over 2,000 lbs) of material to a roll body, and everything in between – from aluminum to tool steel, to cast iron.

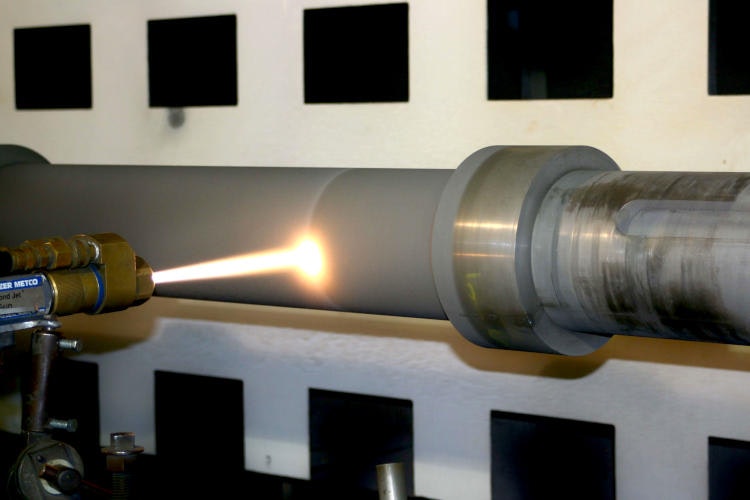

Thermal spray is much more specialized than welding and can have great advantages in the proper application. Its low application temperatures can prove helpful in situations where thermal distortion of the part is a concern, and a selection of extreme-performance formulations can be beneficial for an endless number of applications. Learn more about our Performance Improvement capabilities.

Perhaps more common in less-capable machine shops is the mechanically applied material replacement option. This would typically mean sleeving a journal, bolting in a wear plate, inserting a bolt hole, etc. While this isn’t too common at Atlas, there are certainly situations in which such a repair method is necessary, and many times it requires significant engineering design support.

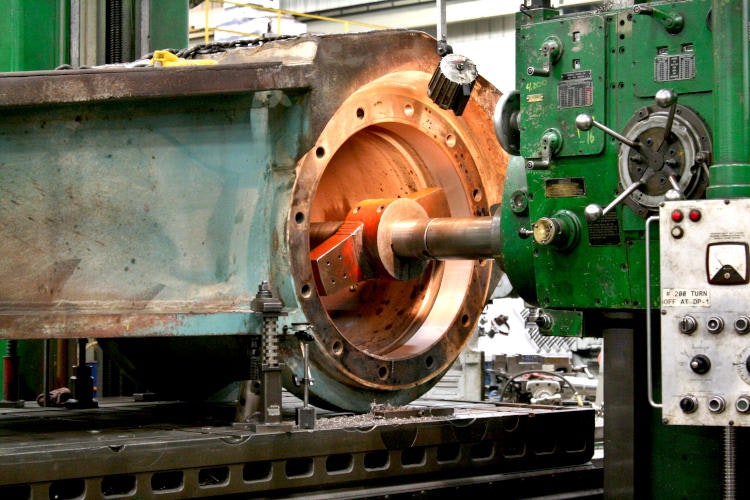

Re-Machining

Re-machining back to spec is possibly the most important step but is oftentimes the simplest as well. In the case of a repair, “to spec” may mean “as specified in the OEM drawing,” “as specified by the customer,” or, more often, “as determined by Atlas’ expertise.” No matter what the specification, Atlas guarantees to provide a high-quality finished product.

Ready for a repair quote?

The larger the component, the more time and money you can save by repairing instead of replacing.

Submit a request to our engineering team for a free repair recommendation and quote.