On-Site Machining and Repair Solutions

What are On-Site or Field Machining Services?

Over the course of being in business since 1907, Atlas has seen an array of terms for these services. On-Site Machining, Onsite Machining, In-Place Machining, Field Machining, etc. On a daily basis, we even find ourselves at Atlas saying “On-Site Machining” or “Field Services” interchangeably. Either way, no matter which term that you like to use, the focus is on providing service at your location or your customer’s location. That means that our highly skilled team will bring the latest portable equipment to your desired location to modify or repair a problem area. Let’s face it, sometimes it is just not possible or economical to try to transport a piece of equipment or machinery to our machine shop. For example, if you need repairs on a Lock & Dam, a bridge, a large press, or even in another country, it will require a company to perform the needed services/work on location. To keep this discussion simple, we’ll use the term “Field Services” going forward.

Atlas’ on-site machining and repair capabilities are difficult to succinctly describe as they are so wide-ranging, and their applications are so diverse.

If you believe your project can only be done in a machine shop or repair facility, but the teardown and transport costs are substantial, give our team a call first. You will be surprised at how comprehensive our field service is and at the level of precision that can be had with our technology and expertise. Submit a request to our on-site engineering team or give us a call at 1-855-4UpTime (855-487-8463) to quickly tap into our knowledge and recommended solutions.

Learn About Our Field Services Capabilities

When downtime isn't an option, Atlas Machine & Supply brings expert service directly to your facility. Our field team delivers on-site machining, mechanical repair, and installation services - where and when you need them.

Click the button below to download our Field Services Booklet and see how we keep your equipment running in the field.

Atlas Machine Field Services

Here at Atlas, field services mean a lot of things to us. From drilling & tapping some new holes in a mill stand for a steel manufacturer to machining a modification launch tower for NASA, we have successfully performed an extremely broad range of field services for our customers. As of today, we have performed various field services for our customers in 46 states and seven countries around the world. On a daily basis, we receive new requests to discuss exciting new projects that most people believe, before speaking with us, just can’t be done. Sometimes our customers are concerned about the harsh environment of the project location, the complexity of the scope of work, or the short time frame in which the project must be completed. Many of these situations present unique challenges and some seem flat out impossible at first glance. But, with the experienced team at Atlas, there are very few rare situations in which we cannot provide a solution. At Atlas, our team of Engineers and highly skilled Field Services Technicians works together on every project to provide our customers with the very best and most economical solution for their project needs. For example, we have created custom-designed portable equipment to perform such tasks as grinding a 10-foot diameter bearing surface and even manufactured our own portable hydraulic CNC milling/drilling machine to perform highly precise operations at the worksite. Our team loves to create solutions for the most demanding circumstances.

Below we have listed some of the services that we perform with our Atlas Field Services just to give you some ideas.

If you ever have any questions regarding one of your upcoming projects or you have an emergency situation, give us a call at 1-855-4UpTime (855-487-8463) (24/7).

.png)

Our Field Crew is Always Ready!

Our overall goal with our Atlas Field Services is to get the customer back in operation as fast as possible. In order to meet that goal, our highly-skilled Field Services Technicians are comprised of Journeyman Machinist, Welders, and high-level Metrology (Laser Tracker/Laser Scanning) Experts.

We do not hire contractors like some other field services companies do to perform the work of our Atlas Machinists or Welders. When our team arrives at your work site, you can rest assured that they are an “Atlas Trained” employee and not temporary labor we just hired yesterday. That’s not who we are or what we believe that our customers deserve. When our customers put faith and trust in us to handle their most challenging tasks, we take it very seriously. It is not just a project or job; it is our reputation on the line. Here at Atlas, we will do what is right for the customer, at the right time, with the right people. That is the Atlas way.

Stud Removal

When it comes to disassembling your equipment for routine maintenance or replacing a broken internal part, there are times when broken or seized studs present a BIG problem. We can utilize our portable equipment to machine out the studs and prevent further damage to the internal threads. On some occasions, the internal threads are already damaged, but we can repair the holes and re-thread them as needed. Either way, we help you ensure that you can get back in operation as soon as possible.

Atlas has an array of portable milling machines, each suited for different use cases. Small key mills can be set up quickly to mill simple keyways in shaft journals, large linear mills can mill any flat surface of any size when coupled with our laser tracker technology, large gantry mills can mill very large areas in one setup, and our CNC mill can perform more specialized drilling and milling operations such as interpolated boring and thread milling. All of these machines can be mounted in any position.

Milling

Atlas has an array of portable milling machines, each suited for different use cases. Small key mills can be set up quickly to mill simple keyways in shaft journals, large linear mills can mill any flat surface of any size when coupled with our laser tracker technology, large gantry mills can mill very large areas in one setup, and our custom CNC mill can perform more specialized drilling and milling operations such as interpolated boring and thread milling. All of these machines can be mounted in any position.

Flange Facing/Circular Milling

Atlas has equipment specifically designed to machine flanges, mounting faces, and bearing surfaces anywhere from 1.5” in diameter, all the way up to 240” (20 feet) in diameter. These machines can utilize single-point tooling, and the larger machines feature hydraulic milling heads.

Grinding

Our linear mills and portable lathes can be outfitted with a grinding attachment for applications that require a finer surface finish. Atlas also has extensive experience in developing custom lapping machines for specialized applications such as thrust faces. Learn more about our custom on-site solutions.

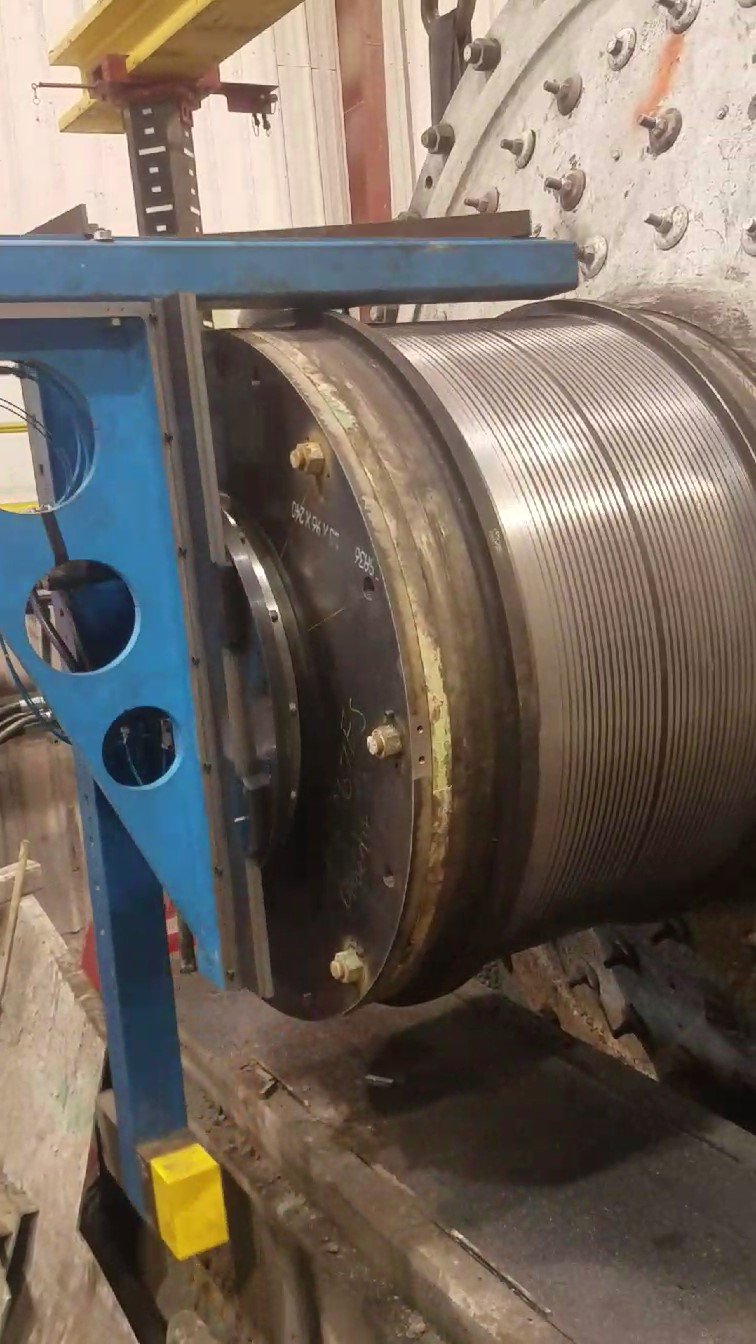

Turning

Most of the time, when a bearing fails, it causes extensive damage to the shaft journal that it runs on. In a lot of cases, the shaft can be removed and sent into our machine shop to repair the damaged shaft journal. But, for those situations where the shaft cannot be removed we have a solution for that. Our portable lathes can be used to repair damaged shaft journals on-site without rotating the shaft. We can rough undercut the shaft journal to prep for welding or a sleeve and finish machine it back to the required tolerance. With our custom grinding attachment, we can even grind the shaft journal if needed. On more than one occasion, we have even turned & repaired a 54” inch diameter shaft journal on-site for a customer. We love a good challenge!

Boring

Atlas has boring bars of all different sizes to accommodate nearly any boring project. The bars themselves range from 1.25” diameter, up to 8” in diameter, and can accommodate bores from 1.5” ID up to 98” ID. Multiple concentric bores? Our boring bars are designed for line boring as well.

Drilling and Tapping

Drilling & Tapping may seem a basic task, and indeed it can be, but precise placement of holes in awkward positions requires portable metrology and specialized machinery. Atlas has a large collection of drills and taps from small to large, and from your typical mag-base hand-fed style to an in-house designed and built CNC drill with interpolation and thread milling capability.

Welding

Many on-site projects are repairs, which typically require adding material to a surface, whether mechanically attached or metallurgically bonded. Atlas has the equipment and the expertise to weld nearly any steel, aluminum, or bronze alloy (and sometimes even cast iron) on-site. For example, if you have a press bed that develops a crack, we can gouge out the cracks, weld them back up, and machine them back to specifications.

Ready to speak with an on-site specialist?

Submit a request to our on-site engineering team or give us a call at 1-855-4UpTime (855-487-8463) to quickly tap into our knowledge and recommended solutions.

Atlas Revolutionizes Galvanizing Pot Maintenance with Innovative Ceramic Coating and Robotic Application

Atlas Revolutionizes Galvanizing Pot Maintenance with Innovative Ceramic Coating and Robotic Application Atlas's breakthrough technology is..

.png)

Breakdown at Steel Mill Requires Quick Response

A sudden major breakdown at a U.S. steel mill reduced its production by 50%--potentially costing the mill hundreds of thousands of dollars in lost..