Atlas Brings First HVAC System to Shop in 118 Years Through UofL Partnership, Strengthening Safety and Quality

Atlas Brings First HVAC System to Shop in 118 Years Through UofL Partnership, Strengthening Safety and Quality

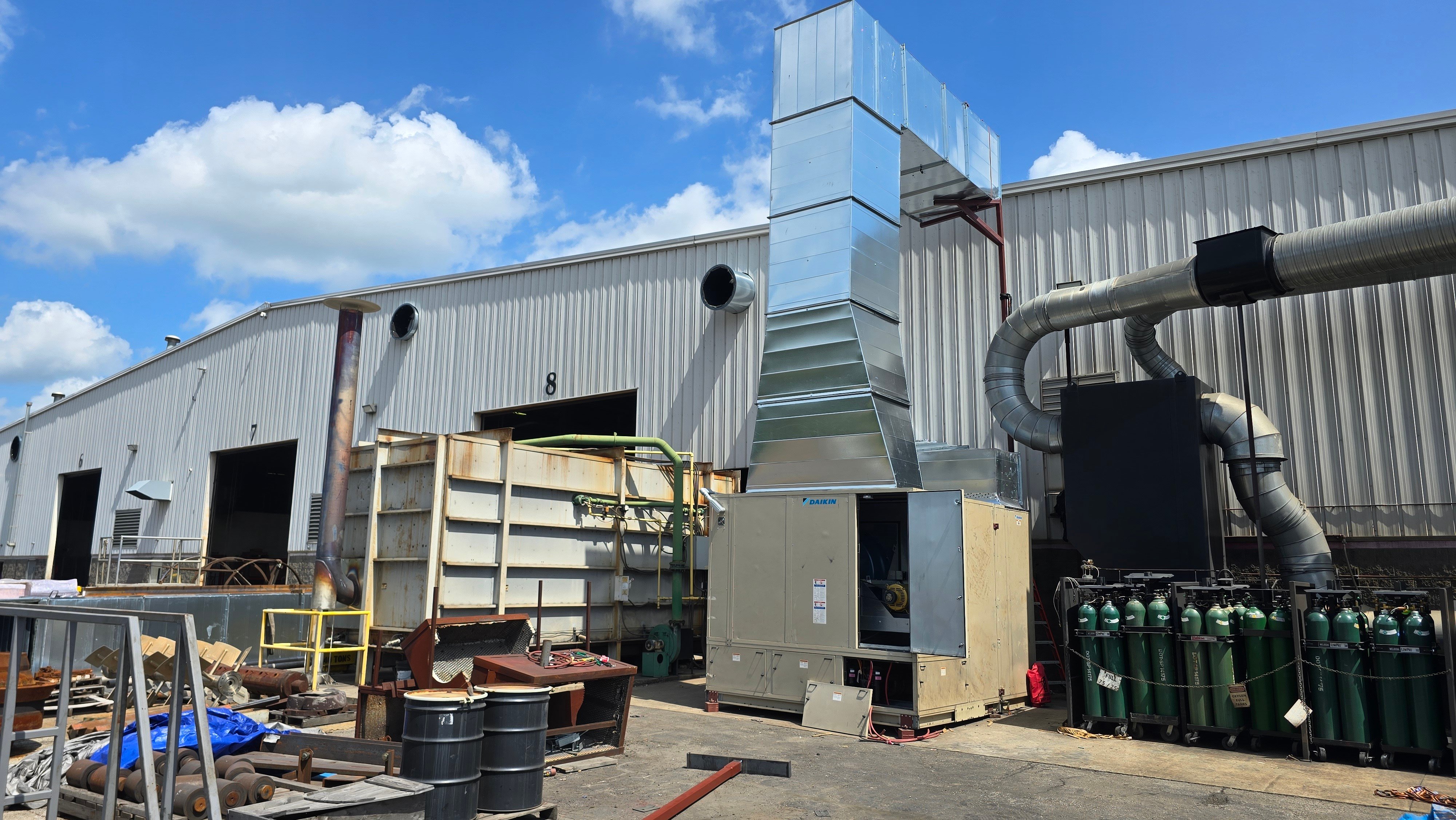

Atlas has completed the installation of its first-ever HVAC system in the machine shop manufacturing space, developed in partnership with the University of Louisville Industrial Assessment Center. The project improves working conditions for employees while incorporating energy-saving technology designed to reduce operating costs and support long-term sustainability.

The system became fully operational in July 2025, marking the first time in Atlas’s 118-year history that the machine shop has been air-conditioned.

Improving Working Conditions for Atlas Employees

Atlas employees perform physically demanding, highly skilled work in challenging industrial conditions. The new HVAC system provides a safer, more comfortable environment, reducing risks related to heat exposure while helping employees stay alert and focused.

“Protecting our team is not just the right thing to do—it’s the foundation of who we are as a company,” said Lance Storey, Safety and Continuous Improvement Director. “Our employees work hard in tough conditions, and they deserve the very best. This project shows how serious we are about safety and about creating an environment where our people can thrive.”

Partnership with the University of Louisville

The University of Louisville Industrial Assessment Center first conducted an energy conservation assessment of Atlas’s shop and recommended a geothermal-assisted cooling system to reduce energy costs while improving working conditions.

The system draws cooling water from the Ohio River underground aquifer, uses it to absorb heat from the HVAC system, and then reinjects the water back into the ground. This approach allows Atlas to obtain most of its cooling energy for free, relying on traditional HVAC systems only for dehumidification.

Additional heat exchangers will be installed inside each HVAC unit to further reduce energy consumption. UofL will also conduct a post-installation study to measure energy savings and share results with other companies interested in similar solutions.

“Partnerships like this demonstrate how industry and academia can work together to drive innovation,” said Jeremy Rydberg, Chief Innovation Officer at Atlas. “By combining our resources and expertise, we’re not only improving conditions for our employees but also advancing energy efficiency practices that can benefit other manufacturers.”

Engineering and Capital Projects Team Contribution

The Atlas Capital Projects Team played an instrumental role in bringing the UofL concept to life. Under the leadership of Michael Almli, Manufacturing Technology Director, the team managed the engineering design work, planning, and physical installation required to make the system a success.

Caleb Cornwell, Project Engineer, took the lead in carrying the project from start to finish—coordinating design efforts, overseeing installation, and ensuring the system met all technical and operational requirements. His hands-on work was supported by the dedicated contributions of Michael Campbell, Timothy Floyd, Israel Lazaro, and Mason Terry, whose combined expertise and teamwork ensured the system was delivered on time and at the highest level of quality.

Together, the Capital Projects Team delivered over $1.5 million in cost savings on a system of this complexity and scale. Their collaboration and problem-solving turned a challenging concept into a fully functioning solution for the shop and its employees, showcasing the strength of a well-coordinated engineering division.

Supporting Safety, Quality, and Sustainability

The new HVAC system addresses multiple priorities for Atlas:

- Employee Safety: Reduces the risk of heat-related illnesses such as dehydration, fatigue, and heat exhaustion.

- Product Quality: Stable temperatures help employees maintain the precision and consistency required for high-quality machining work. A Cornell University study found that temperatures outside the ideal range (below 68°F or above 77°F) can increase error rates by 74%.

- Energy Efficiency: Expected annual energy savings are projected to be well into six figures, with the potential for a $250,000–$300,000 DOE grant to offset project costs.

-1.png)