Revving Up Efficiency: How Hitachi Astemo Revamped Their Compressed Air System with Compressed Air Solutions by Atlas Machine

.png)

Revving Up Efficiency: How Hitachi Astemo Revamped Their Compressed Air System with Compressed Air Solutions by Atlas Machine

When Hitachi Astemo needed an upgrade to its compressed air delivery system, Atlas Machine & Supply's Compressed Air Division was here to help!

A TRANSFORMATIVE UPGRADE

Infrastructure upgrades are essential for maintaining the efficiency and reliability of any facility. When these upgrades also promise long-term benefits, they become even more critical. Such was the case for Hitachi Astemo, a major producer of automotive brake pads and shock absorbers and a primary supplier to Honda. In the realm of innovative automotive manufacturing, every element of the production process matters. Hitachi Astemo recently underwent a transformative upgrade to its compressed air delivery system, led by Atlas Machine & Supply Industrial Products Group. With Atlas Machine's expertise, they didn't just replace old infrastructure—they revolutionized it, unlocking new levels of efficiency, reliability, and cost savings.

Hitachi Astemo, located in Sunbury, Ohio.

A LEGACY OF EXCELLENCE

Atlas Machine & Supply, established in 1907, has been a leader in the compressed air industry since the 1950s. Representing Sullair compressed air system products, Atlas Machine now operates eight branches across Kentucky, Tennessee, Ohio, and Indiana.

Hitachi Astemo, located in Sunbury, Ohio, boasts a 281,000-square-foot facility with 700 employees. With plants across the Midwest, the company supports Honda’s domestic needs, making efficiency and reliability crucial for its operations.

THE CHALLENGE

Hitachi Astemo’s previous compressed air system had become outdated and inefficient. The system included two 400-horsepower (hp) fixed-speed air compressors and five 200-hp fixed-speed air compressors, all managed by an antiquated master control system. This setup led to frequent cycling of air compressors, unstable pressure levels, high maintenance costs, and inflated operational expenses.

IDENTIFYING THE ISSUES

Before any upgrades, Atlas Machine conducted a comprehensive audit of Hitachi Astemo’s system. This week-long audit revealed several key issues:

- Overuse of air compressors due to an outdated master controller.

- Pressure instability requiring higher operational pressures.

- High maintenance costs and overall inefficiency.

"They needed a little more sophistication," said Andy Poplin, Senior Vice President of Atlas Machine & Supply Industrial Products Group. "The client was essentially cycling air compressors more than they should and also had to have the pressure higher because of the load/no load scenario. They had to run higher pressure to maintain the target pressure for the operation of the facility."

Andy Poplin, Atlas Machine & Supply Industrial Products Group Senior Vice President.

THE SOLUTION

Based on the audit findings, Atlas Machine recommended a complete system overhaul. The proposal included:

- Replacing three of the 200-hp air compressors with a Sullair two-stage 300-hp spiral valve rotary screw air compressor and two single-stage 160-hp spiral valve rotary screw air compressors.

- Installing ACES, an advanced master controller based on the Allen Bradley RSLogix 5000 platform.

The new system reduced the number of active air compressors from seven to three, utilizing Sullair’s electronic spiral valve technology to automatically adjust the air supply according to demand.

"We made sure we had the right air compressors and control system for the job at the right time. We introduced the variable displacement machines that can help minimize the loading and unloading necessary because the machines would modulate efficiently on the spiral well, so we were able to lower the playing pressure as well," Poplin added.

OVERCOMING CHALLENGES

The project, spanning from April 2023 to February 2024, faced significant logistical challenges. The large 400-hp air compressors were located on a mezzanine in a plant that had expanded over time, complicating the removal and installation process. Despite these challenges, the installation was successfully completed.

"It took a while because the installation of the air compressors was a challenge," Poplin said. "They had these large 400-hp air compressors on a mezzanine in a plant that grew after they set the air compressors, so the logistics of getting those out and getting a new air compressor in was a challenge."

TRANSFORMATIVE RESULTS

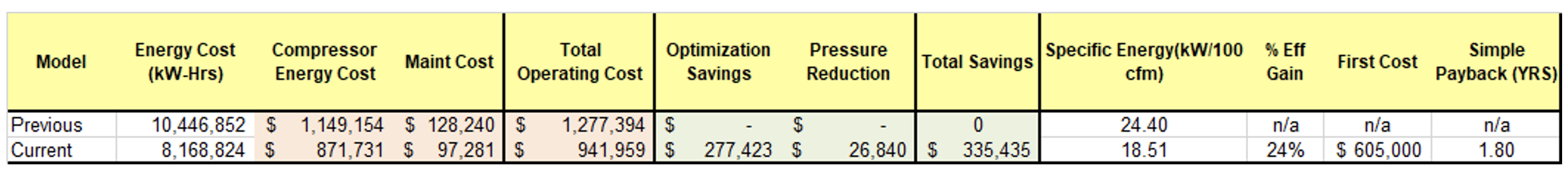

The upgraded system delivered substantial improvements in efficiency and cost savings:

- Energy costs reduced by 21.95%.

- Air compressor energy costs dropped by 24.14%.

- Maintenance costs decreased by 24.14%.

- Total operating costs fell by 26.25%, from $1,277,394 to $941,959.

ADVANCED TECHNOLOGY AT WORK

Sullair’s Spiral Valve Technology: The Sullair LS160 air compressors with electronic spiral valves automatically adjust the air supply, minimizing the need for frequent loading and unloading. This technology is crucial for maintaining optimal pressure levels and reducing energy consumption, thereby enhancing the overall efficiency of the system.

ACES Master Controller: This advanced system goes beyond simple pressure monitoring, incorporating flow-based and location-based decision-making. It offers extensive customization and flexibility, allowing Hitachi Astemo to optimize its operations continuously. By providing detailed insights and control, ACES helps in fine-tuning the system to meet varying demands efficiently.

"It can control the air compressors based on input information, more so than just pressure. It can do flow-based decisions, it can do location-based decisions; it's very customizable and flexible," Poplin said. "It's unlimited in terms of what type of air compressor you control, and what type of information we can use to make these decisions. An extremely open platform."

IMPORTANCE OF EFFICIENCY AND COST-SAVINGS

The results and products used in this upgrade are vital for several reasons:

- Efficiency: Modern, advanced air compressors and control systems ensure that the compressed air system operates at peak efficiency, reducing waste and unnecessary energy consumption. This not only enhances the performance of the entire production process but also contributes to the sustainability goals of the facility.

- Cost-Savings: Significant reductions in energy and maintenance costs directly impact the bottom line, allowing the company to allocate resources more effectively. Lower operational costs mean higher profitability, which is essential for maintaining a competitive edge in the automotive industry.

LOOKING AHEAD

Atlas Machine and Hitachi Astemo are already planning further improvements. Future projects include:

- Separating air knives from the compressed air system and using blowers to reduce energy consumption.

- Correcting undersized pipe drops to lower system pressure requirements.

- Adding cellular connections for remote monitoring and control.

These planned improvements reflect Hitachi Astemo's satisfaction with Atlas Machine's expertise and the positive outcomes of the recent upgrades. The willingness to continue investing in further enhancements underscores the successful partnership between the two companies and their commitment to continuous improvement.

"That's our next phase with this client: to see if we can move outside of the air compressor room from the supply side into the demand side and capture even more savings," Poplin noted.

CONCLUSION

The successful upgrade at Hitachi Astemo highlights the significant benefits of modernizing compressed air systems. By addressing inefficiencies and reducing operational costs, Atlas Machine has not only improved Hitachi Astemo’s current operations but also paved the way for future enhancements. This project stands as a testament to the power of strategic infrastructure upgrades in driving long-term efficiency and reliability. The ongoing collaboration between Atlas Machine and Hitachi Astemo promises even greater advancements, ensuring that Hitachi Astemo remains at the forefront of innovative automotive manufacturing.

Andy Poplin, Senior Vice President of Atlas IPG, remarked, "As leaders in the compressed air industry, we're proud to have partnered with Hitachi Astemo to revolutionize their infrastructure. By integrating advanced technologies and strategic upgrades, we've not only enhanced efficiency and reliability but also set a new standard for operational excellence in automotive manufacturing."